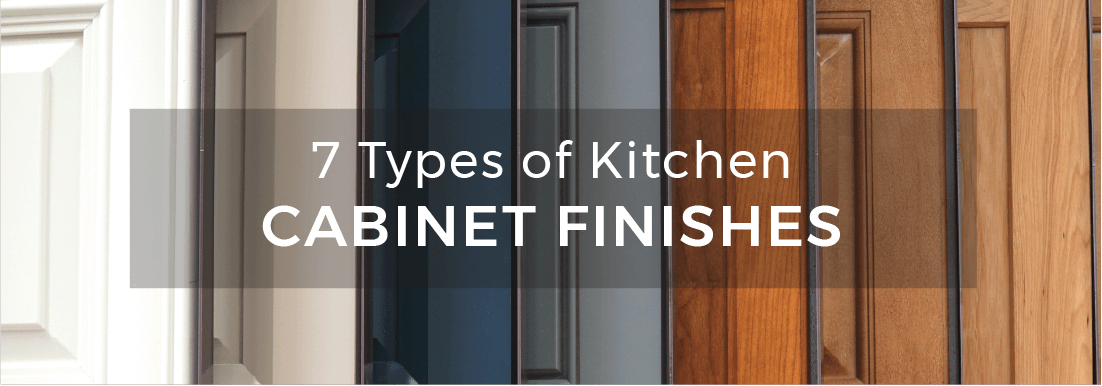

You've nailed down your kitchen layout and decided on your cabinet style. It's now time to bring some personality into your space with cabinet finishes. Your cabinet finish can have subtle variations or stand-out colors depending on the level of detailing and customization techniques used.

Understand the options that will best suit your space by considering what finishes are available for your kitchen cabinets, along with your budget and desired durability. Order a variety of samples before making your final decision for a finish that perfectly complements the style and design of your new kitchen. In this post, we'll cover the different types of cabinet finishes: the techniques used to apply them, and the pros and cons of each.

Cabinet Finishes

Cabinet finishes are the last application of color or laminate that gives cabinetry the final aesthetic. Depending on your cabinet's material, the application's final appearance may fluctuate slightly. Options for cabinet finishes include:

1. Waterborne Finish

Eco-friendly manufacturers, like Forevermark Cabinetry, offer a waterborne ultra-violet (UV) finish. You'll find this finish in most of our RTA and stock cabinets, like our Nova Light Gray. This product is manufactured using Sherwin-Williams coatings, to offer high-performance cabinets manufactured specifically to reduce environmental impact.

The waterborne finish is scratch-resistant, low in volatile organic compounds (VOCs), and formaldehyde-hazard free. Because waterborne finishes are dispersed in water, there is less downtime between the time of application and use. These solutions satisfy the highest standards for performance while meeting or exceeding stringent regulatory requirements.

Technique:

This finish dries quickly, and is then cured with UV light. The aesthetic is similar to that of varnished, stained, or painted kitchen cabinets

| Pros | Cons |

|---|---|

| Easy to clean, scratch resistant, and resists yellowing with age. | Difficult to apply and slightly more expensive. |

| Pros |

|---|

| Easy to clean, scratch resistant, and resists yellowing with age. |

| Cons |

| Difficult to apply and slightly more expensive. |

2. Stained Cabinets

Stain is applied on wood to change the color, enhance the grain, or to protect cabinets from damage. For example, Mocha Shaker kitchen cabinets resemble natural wood using colors like oak, walnut, or pecan. Cabinets can be stained underneath another finishing technique to create an alternative final aesthetic.

Technique:

Generally hand-rubbed, these finishes often require several rounds of sanding and restaining.

| Pros | Cons |

|---|---|

| Different areas in the wood soak up different amounts of stain leaving a crafted, individualized look. | Fewer color options than painted cabinets. |

| Pros |

|---|

| Different areas in the wood soak up different amounts of stain leaving a crafted, individualized look. |

| Cons |

| Fewer color options than painted cabinets. |

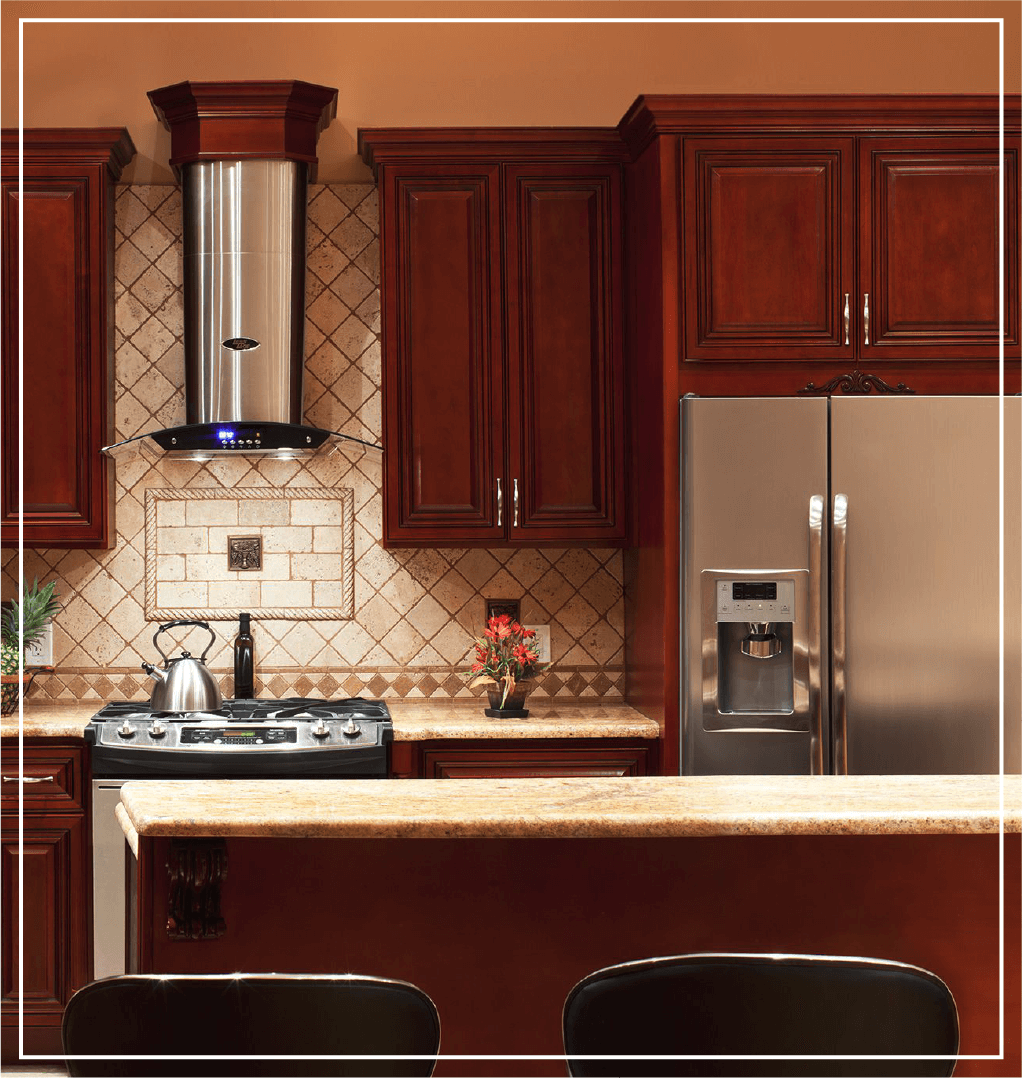

3. Glazed Cabinets

A glazed cabinet finish can alter the color and texture of cabinetry, often used when applying faux-finishes. A glazed finish can be applied on top of paint or stain to accentuate the details in the species of wood in the cabinetry. Our Cherryville kitchen cabinets feature this type of finish.

Technique:

Applied over a finished base coat of paint or stain then rubbed off by hand. Varnish is often applied as a top coat to increase durability.

| Pros | Cons |

|---|---|

| Adds visual depth and interest to stained cabinets. Although slightly pigmented, the color is either transparent or semi-transparent. | A premium finish requiring heavy handwork, often more expensive than alternatives. |

| Pros |

|---|

| Adds visual depth and interest to stained cabinets. Although slightly pigmented, the color is either transparent or semi-transparent. |

| Cons |

| A premium finish requiring heavy handwork, often more expensive than alternatives. |

4. Natural Cabinets

A natural wood finish does not use stains or dyes and does not alter the color of the wood. Typically these finishes are clear so the natural color is visible beneath the protective layer giving a raw look. Depending on the species of wood, the durability will vary.

Technique:

This finishing process rotates sanding and oiling with Tung, mink, linseed, or mineral oil.

| Pros | Cons |

|---|---|

| Brings out the color variations within a piece of wood. | Lack of uniformity and color choice. |

| Pros |

|---|

| Brings out the color variations within a piece of wood. |

| Cons |

| Lack of uniformity and color choice. |

5. Painted Cabinets

Painted cabinet finishes, like our Thompson White cabinets, offer robust color options but often cover the natural characteristics found in the wood. Trending paint colors are a great starting point when choosing your ideal shade.

Technique:

Painted cabinets are also referred to as opaques. Many painted cabinets include a varnish top coat for added durability.

| Pros | Cons |

|---|---|

| Light clean look for matching colors throughout the home. | Likely to chip, show dents, and can rub off in highly used areas. |

| Pros |

|---|

| Light clean look for matching colors throughout the home. |

| Cons |

| Likely to chip, show dents, and can rub off in highly used areas. |

6. Varnished Cabinets

Most manufacturers of modern assembled kitchen cabinets use a polyurethane catalyzed varnish as a topcoat. Varnish provides cabinetry with extra durability and heat resistance. All-natural cabinets will require a varnish, at a minimum, as a finish.

Technique:

Traditional varnish is a combination of oil and resin. As it dries, it undergoes a chemical reaction creating a hard, dissolving-resistant surface.

| Pros | Cons |

|---|---|

| Resists age-related yellowing, heat, and corrosion. | Susceptible to chips, dings, and wear. |

| Pros |

|---|

| Resists age-related yellowing, heat, and corrosion. |

| Cons |

| Susceptible to chips, dings, and wear. |

7. Distressed Cabinets

Distressed cabinets are a type of painting technique to give new furniture an aged appearance. The finish is created by making the paint coat seem worn or scratched using different techniques with the stain, paint, or glaze.

Technique:

If using a single coat, the paint is sanded or scraped. If using two coats, the top coat is quickly wiped away.

| Pros | Cons |

|---|---|

| Color variations add character and a timeless, aged look. | Likely to rub off and chip in highly used areas. |

| Pros |

|---|

| Color variations add character and a timeless, aged look. |

| Cons |

| Likely to rub off and chip in highly used areas. |

Kitchen Cabinet Finishes FAQs

The finish you choose on your cabinets can accentuate your kitchen color scheme, enhance the wood grain of your cabinets, and even provide protection from normal wear. For everything in between, refer to the frequently asked questions and corresponding answers below.

What is the best finish for kitchen cabinets?

Waterborne UV finishes are the best quality for creating the most durable cabinetry. With its eco-friendly composition, and fast-drying features, waterborne UV cures are the top of the line cabinet finish in the marketplace. Whatever finish you choose, add a polyurethane varnish on top. The finish is easy to apply and lengthens the lifespan of your cabinetry while accentuating the color of the wood.

What is the best color for kitchen cabinets?

The best color for your kitchen cabinets will depend on your personal preference and kitchen color scheme. Take note of how much natural light your room offers during different times of the day. From there, consider color combinations such as blue and white, black and white, blue and brown, green and white, or all black.

Is there a special paint for kitchen cabinets?

Different paints will have a different effect on your cabinetry. Adding a polyurethane varnish as a top coat will help prolong the life of your cabinets while resisting yellowing and corrosion. It's important to note, however, that not every varnish will suit every species of wood.

Do you paint both sides of kitchen cabinet doors?

You should paint both sides of your kitchen cabinet doors. However, the inside of your cabinet boxes do not need to be repainted.

What color cabinets look best with stainless steel appliances?

White, gray, brown, and vibrant colors all have a cohesive look when paired with stainless steel appliances. Combine color swatches of different hues to decide what looks best in your space.

Cabinet finishes are a focal point of your kitchen. Go bold with a bright color, or keep it uniform with a natural finish to complete the look in your space. Whatever cabinet finish you decide on, take personalization one step further by adding complimentary cabinet handles or a stunning kitchen faucet.